Automation has become a cornerstone in modern lab operations, helping reduce manual errors, speed up workflows, and optimize resource usage. AFYS3G’s equipment, including the Lambda768 Information Marking System and the Delta50 High-Speed Rack Reader, is designed to integrate seamlessly into these automated workflows, providing labs with reliable, scalable solutions for sample management.

Automated laboratory workflows offer numerous advantages:

- Improved Accuracy: reduces human error in labeling, handling, and scanning samples.

- Increased Throughput: enables the processing of thousands of samples efficiently.

- Consistent Traceability: maintains a reliable record of sample identity, critical for research integrity and regulatory compliance.

- Optimized Resource Use: frees lab personnel for higher-value tasks while minimizing sample handling errors.

Incorporating automated systems into laboratories is no longer optional; it is essential for scaling operations and maintaining high standards.

AFYS3G Solutions for Seamless Automation

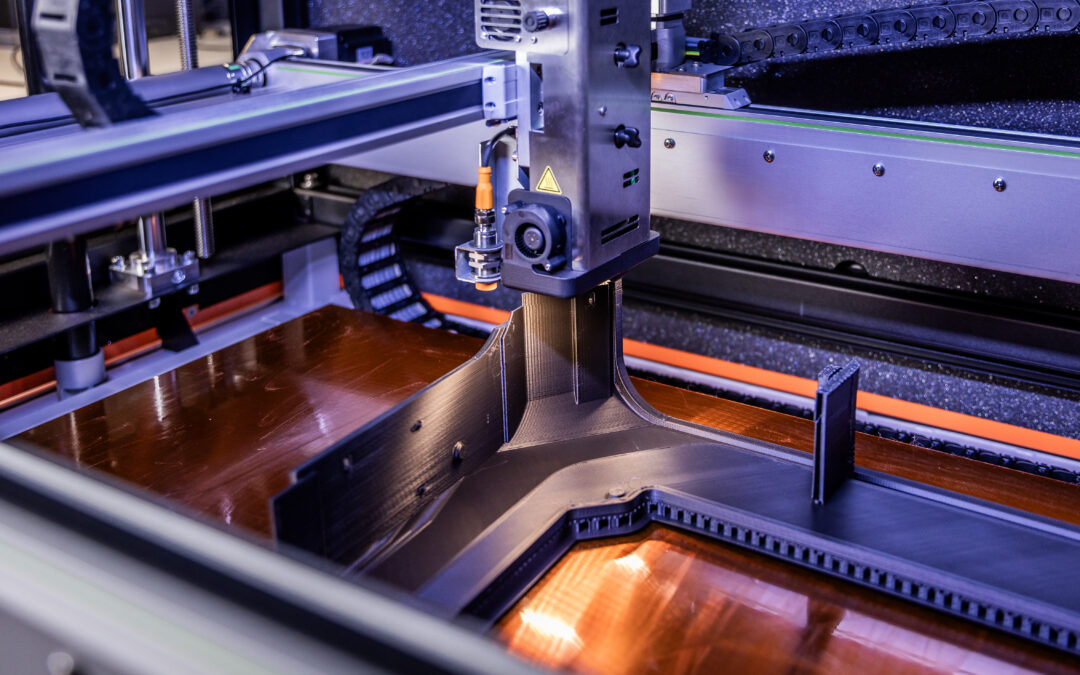

AFYS3G offers a range of equipment designed to support automated sample handling systems, streamlining workflows and ensuring traceability. The Lambda768 Information Marking System allows laboratories to permanently mark sample tubes with custom text, logos, or 2D Data-Matrix codes. Fully compatible with automation systems, it delivers accurate, high-quality markings, works seamlessly with robotic arms and automated tube handling systems, and produces durable labels that resist wear, peeling, or fading even under extreme storage conditions. This eliminates the risk of mislabeling and enables smooth, automated identification workflows for high-volume laboratories. Complementing this, the Delta50 High-Speed Rack Reader enhances traceability by scanning entire racks in seconds, supporting rapid 2D code reading for high-density racks, integration with automated cappers, decappers, and storage robots, and seamless data transfer to Laboratory Information Management Systems (LIMS). By combining the Lambda768 and Delta50, laboratories can fully automate the marking, scanning, and data logging process, ensuring every sample is accurately tracked from the moment it is processed.

Integrating AFYS3G systems into automated workflows delivers tangible benefits:

- Enhanced Efficiency: faster sample identification, capping, and storage

- Error Reduction: permanent laser markings and rapid rack scanning prevent misidentification

- Scalability: supports high-throughput laboratories and growing biobanks

- Compliance: maintains GLP/GMP traceability standards without manual intervention

With these systems, laboratories can handle high volumes of samples with confidence, knowing that accuracy and traceability are never compromised.

AFYS3G systems, including the Lambda768 and Delta50, provide reliable, scalable, and fully integrable solutions that streamline workflows, enhance sample traceability, and reduce errors. By incorporating these systems into automated lab operations, laboratories can increase throughput, protect sample integrity, and focus on advancing research rather than managing manual processes. Discover more about AFYS3G automation solutions and explore how our equipment can transform your laboratory workflows on our product page.