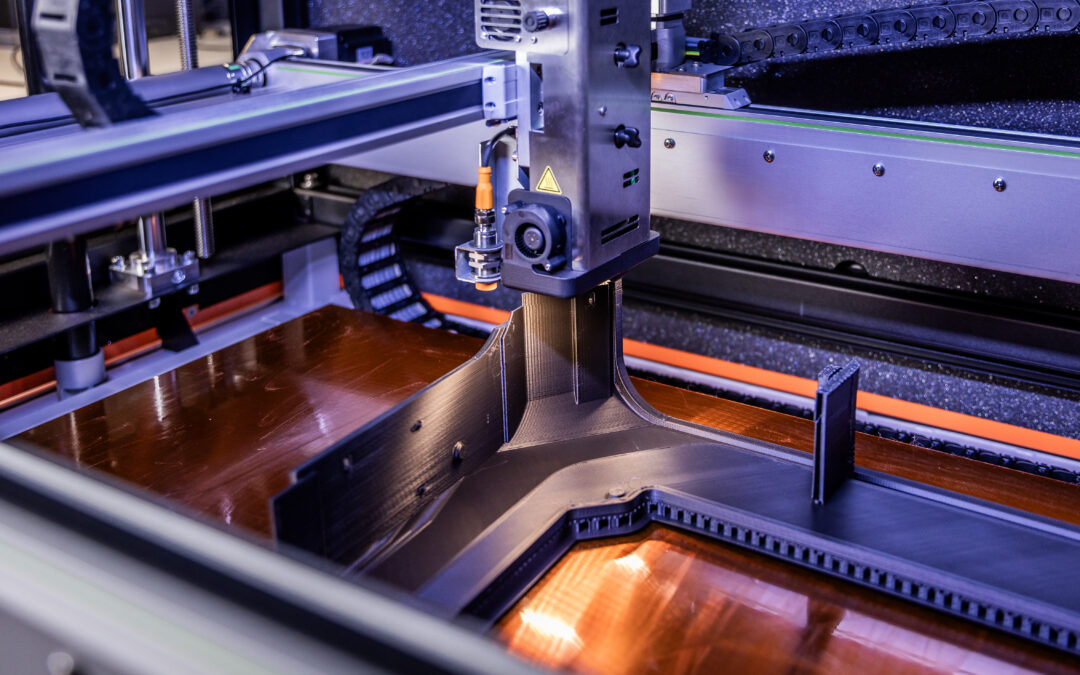

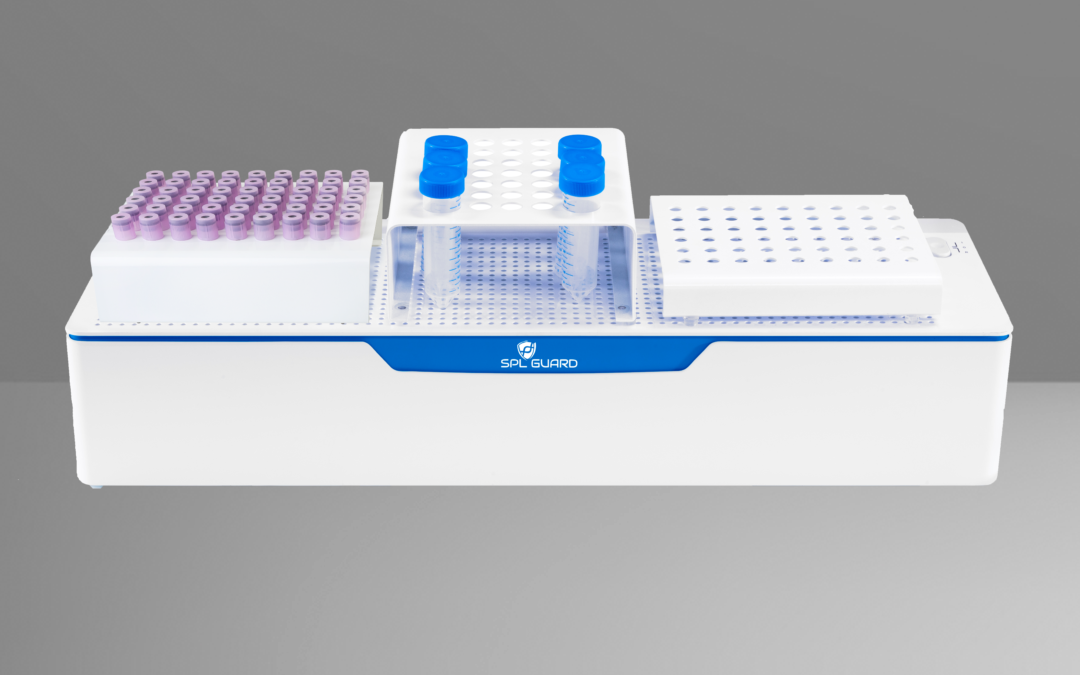

The versatile Lambda8 is a manual laser marker that can not only mark tubes, but also racks in ANSI/SLAS format, caps, microscope slides, and materials such as aluminum, stainless steel and titanium. Since a wide range of adapters can be used with the Lambda8, it can accommodate a variety of labware and other materials. But which tubes are compatible with the Lambda8? What is the throughput? And how can you laser etch sample specific information on the tube? Within this post, we’ll answer the most frequently asked questions of the Lambda8. Do you still have questions left after this post? Our distributor NBS Scientific recently gave a demo of the Lambda8, the video will be shared at the end of the post with you so you can see how the Lambda8 operates for yourself!

What is the approximate speed/throughput of the Lambda8?

This is strongly depending on the number of tubes in the adapter and the information you want to laser. Typically we estimate the laser time 1-3 second/tube and is related to the settings (single/double laser, power, speed etc). Please be aware that the time needed to pick and place the tubes in the adapter (including setting the software and open/close the door) is more time consuming than the laser time itself.

What tubes are compatible with the Lambda8?

Most important is that the tube is not transparent, it should have pigment to be able to laser etch. When the tube is transparent the laser beam will just go through the tube without result. The Lambda8 has tested laser etching the Micronic hybrid tubes and the FluidX Jacket tubes, if you are working with other tubes that have pigment in it we are always happy to perform tests with labware to see if it is compatible as well.

On the front of the unit it says Class 1 Laser Product but we know that a Class 4 Laser is used. What is the difference between a Class 4 Laser and a Class 1 Laser Product?

Class 4 lasers are hazardous for eye exposure. They can also burn skin and materials, especially dark and/or lightweight materials at close range. They should be used with extreme care. It is a Class 1 Laser Product due to the special safety glass in the front door, this reduces the risk to a Class 1. So, when the laser is on, the door should always be closed. In addition the door has a locking sensor, which prevents the door from opening during the process. Due to safety reasons we have to label the unit this way.

Does the laser damage the tube if it marks directly into the surface? Some tubes are thinner than others.

The laser encrypts only the surface, there is absolutely no risk of the sample will get damaged.

How does someone laser-etch sample specific information (LIMS integration)?

The software included to the Lambda8 is very comprehensive, it has the option to connect or refer to another program like Excel or LIMS that you are using.

What type of general maintenance is required by the user? Wipe down inside daily/weekly/monthly/after x amount of uses? Any other tasks that need to be done?

The machine itself will not get dirty due to the standard use, only when the user inserts leaking/splashing tubes. We recommend a monthly cleaning.

Are extended service contracts offered? If so, what is covered?

Yes, we offer a service contract. For the Lambda8 the following is covered:

- Full cleaning

- Calibration of the Laser

- Update software

- Check of all the power circuits

- Full check of air filtration system and the replacement of the filters

Why is an air filter needed and how does the air filtration system work?

As the laser is ‘burning’ inside, the plastic extraction and cleaning of the air is required. The air filtration system is attached manually.

Do you have any questions left or do you want to request a quote? In the video below you can find a Demonstration by our distributor NBS Scientific in the US. For a quote email us at info@afys3g.com