At AFYS3G, we design and build advanced lab devices that make everyday work in the life sciences faster, more reliable, and easier to manage. Our systems help researchers track and process biological samples – from marking and labeling labware to barcode scanning, thawing frozen specimens, and mixing or heating samples for experiments.

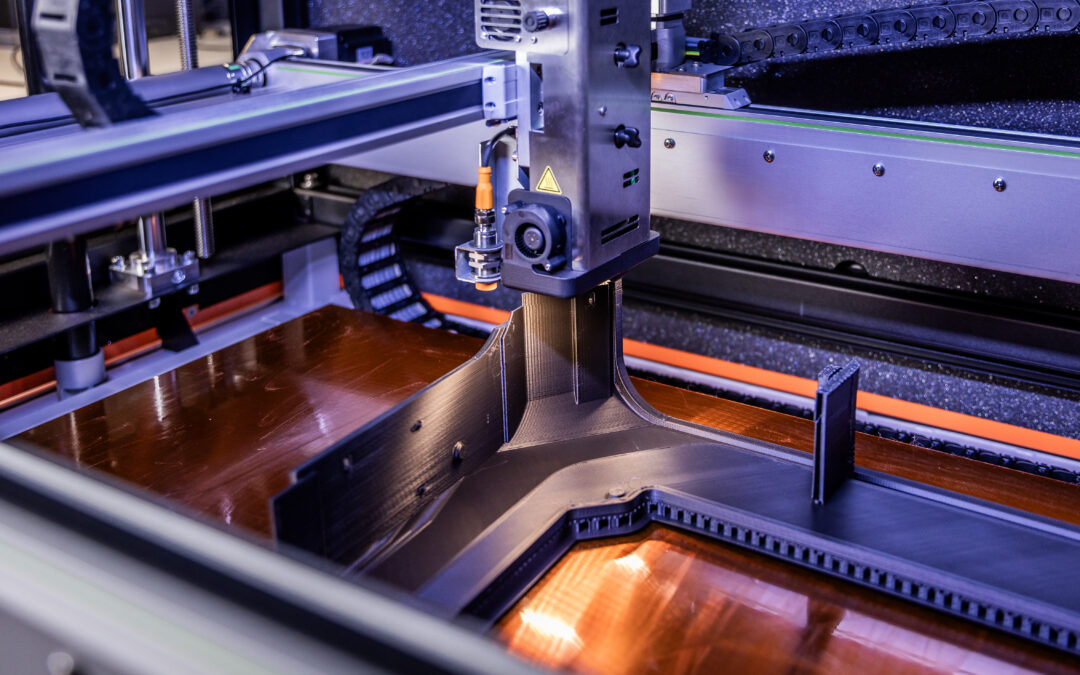

To meet the demands of a fast-changing industry, we needed a smarter, more flexible way to produce the housings for our equipment. Traditional methods like die casting, injection molding, and vacuum forming required long lead times and costly tooling. Instead, we turned to large-format 3D printing and the results transformed our production process.

“We needed a large-format 3D printer to create housings for equipment. We didn’t want to invest in large amounts of tooling like die casting, injection molding, or vacuum molding. So we thought 3D printing would be a good alternative.”

— Harry Epping, Manufacturing Process Engineer, AFYS3G

Why We Chose A LARGE-FORMAT 3D PRINTER

1. Large-Scale Build Volume

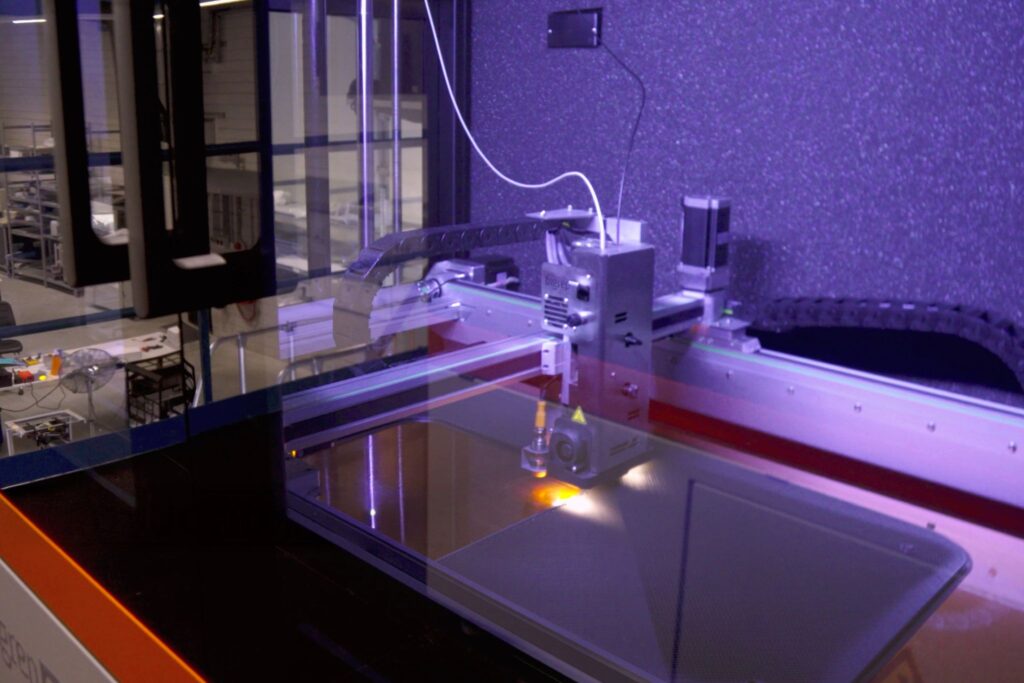

With a build volume of 1000 x 500 x 500 mm, the BigRep STUDIO (large format 3D printer) gives us the capacity to print large housings and mechanical parts while maintaining a compact production footprint.

2. Safety and Compliance

The STUDIO’s insulated enclosure and BOFA air filtration system ensure safe operation and full compliance with health and safety standards. Any fumes are directed into the filtration system and purified through HEPA filters.

3. Reliable End-Use Parts

Using BigRep’s HI-TEMP and other filaments, we produce strong, precise, and aesthetically finished components. After post-processing, our housings are nearly indistinguishable from injection-molded or die-cast parts – but with greater design freedom.

4. Remote Monitoring

BigRep CONNECT enables our engineers to track print progress remotely, analyze workflows, and prevent errors. This visibility helps us optimize production and meet deadlines consistently.

The efficiency gains were so significant that we invested in a second 3D printer to keep up with demand and eliminate bottlenecks caused by long print cycles.

From Print to Production: AFYS3G’s Labware Marking System

Each housing begins with a full trial assembly to confirm fit and function before post-processing. The workflow then includes:

- Surface finishing: sanding and filling to achieve smooth exteriors.

- Custom coatings: functional painted surfaces and high-gloss finishes for select parts.

- Targeted post-processing: internal components require minimal finishing while inserts add strength and stability.

This tailored approach strikes the perfect balance between aesthetics, durability, and efficiency — producing housings that look and perform like conventionally manufactured parts at a fraction of the cost and time.

The Results: Faster, Smarter Manufacturing

By integrating the BigRep STUDIO into our workflow, AFYS3G has:

- Reduced lead times from months to weeks

- Lowered production costs by eliminating expensive tooling

- Gained the flexibility to rapidly prototype, test, and refine designs

- Delivered strong, lightweight, and reliable end-use parts

“We use 3D printing for almost everything. If there is a possibility to 3D print parts, we will always take the opportunity.”

— Harry Epping

In the fast-moving world of life sciences, agility is everything. For AFYS3G, 3D printing has become more than just a tool — it’s a cornerstone of our production process, enabling us to create innovative, high-quality lab equipment faster and more cost-effectively than ever before.